Tricky Testing Tools for Eddy-Current Proximity Probes

The monitoring of rotor vibrations and axial shaft positions ranks among the most important features to ensure protection against severe damage to turbomachinery.

It is common practice to regularly check pressure, temperature and flow measurements, however, the vibration and axial position measurements are usually only checked in very exceptional cases. One is usually content with being able to set the probe distance by measuring the GAP voltage.

Especially for this purpose, kmo turbo has developed two compact and easy-to-use tools, which are available in a rugged protection case:

LoopChecker

Funtional Testing of the Entire Loop

Installed within the compact housing is a measuring surface consisting of the shaft material; as opposed to the clamped probe, this is forced to oscillate at a defined value. The LoopChecker is controlled by a compact handheld device. Thanks to a holding magnet on the back, the device can be conveniently mounted at practically any position. The installed battery allows several hours of operation. Alternatively, the LoopChecker can also be operated via the provided power adapter.

The system oscillates in the range of 105 to 125 Hz. By means of a handheld control unit 4 amplitudes up to 250 μptp can be set and stored.

The LoopChecker enables testing of the entire loop or measuring circuit, i.e. eddy-current proximity probe, wiring, evaluation unit, indication and monitoring unit!

The LoopChecker allows the use for outer diameters from 8 ... 22 mm (forward-mount probes as well as for reverse-mount probes installed in a probe holder).

Request a quotation:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Interested in becoming international distribution partner? Please Contact: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

SensiChecker

Determining the Sensitivity

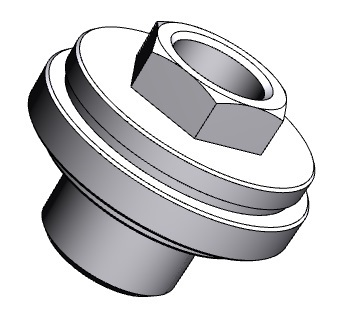

In order to determine the sensitivity of the measuring circuit, the probe is inserted into the SensiChecker and clamped. By turning from one snap-in position to the next, the distance is respectively altered by 0.2 mm (KS05-A1). Optionally a version with 10 mils per click is available (KS05-A2). If the respective GAP voltage is entered into a diagram (click for free evaluation form! ...), the sensitivity can be read directly.

In order to determine the sensitivity of the measuring circuit, the probe is inserted into the SensiChecker and clamped. By turning from one snap-in position to the next, the distance is respectively altered by 0.2 mm (KS05-A1). Optionally a version with 10 mils per click is available (KS05-A2). If the respective GAP voltage is entered into a diagram (click for free evaluation form! ...), the sensitivity can be read directly.

The SensiChecker allows the use for outer diameters from 8 ... 22 mm (forward-mount probes as well as for reverse-mount probes installed in a probe holder).

Using the optional adapter screw KS05-B1, the SensiChecker can also be screwed into a 3/4" NPT bore at the original measuring point. In case of a disassembled shaft, the optional prismatic shaft adapter KS05-D1 can be used to measure against the original shaft material.

EVALUATION FORM SENSICHECKER (XLS) ...

Request a quotation:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Interested in becoming international distribution partner? Please Contact:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!