The monitoring of rotor vibrations and axial shaft positions ranks among the most important features to ensure protection against severe damage to turbomachinery.

It is common practice to regularly check pressure, temperature and flow measurements, however, the vibration and axial position measurements are usually only checked in very exceptional cases. One is usually content with being able to set the probe distance by measuring the GAP voltage.

Especially for this purpose, kmo turbo has developed two compact and easy-to-use tools, which are available in a rugged protection case:

LoopChecker

Funtional Testing of the Entire Loop

Installed within the compact housing is a measuring surface consisting of the shaft material; as opposed to the clamped probe, this is forced to oscillate at a defined value. The LoopChecker is controlled by a compact handheld device. Thanks to a holding magnet on the back, the device can be conveniently mounted at practically any position. The installed battery allows several hours of operation. Alternatively, the LoopChecker can also be operated via the provided power adapter.

The system oscillates in the range of 105 to 125 Hz. By means of a handheld control unit 4 amplitudes up to 250 μptp can be set and stored.

The LoopChecker enables testing of the entire loop or measuring circuit, i.e. eddy-current proximity probe, wiring, evaluation unit, indication and monitoring unit!

The LoopChecker allows the use for outer diameters from 8 ... 22 mm (forward-mount probes as well as for reverse-mount probes installed in a probe holder).

Request a quotation:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Interested in becoming international distribution partner? Please Contact: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

SensiChecker

Determining the Sensitivity

In order to determine the sensitivity of the measuring circuit, the probe is inserted into the SensiChecker and clamped. By turning from one snap-in position to the next, the distance is respectively altered by 0.2 mm (KS05-A1). Optionally a version with 10 mils per click is available (KS05-A2). If the respective GAP voltage is entered into a diagram (click for free evaluation form! ...), the sensitivity can be read directly.

In order to determine the sensitivity of the measuring circuit, the probe is inserted into the SensiChecker and clamped. By turning from one snap-in position to the next, the distance is respectively altered by 0.2 mm (KS05-A1). Optionally a version with 10 mils per click is available (KS05-A2). If the respective GAP voltage is entered into a diagram (click for free evaluation form! ...), the sensitivity can be read directly.

The SensiChecker allows the use for outer diameters from 8 ... 22 mm (forward-mount probes as well as for reverse-mount probes installed in a probe holder).

Using the optional adapter screw KS05-B1, the SensiChecker can also be screwed into a 3/4" NPT bore at the original measuring point. In case of a disassembled shaft, the optional prismatic shaft adapter KS05-D1 can be used to measure against the original shaft material.

EVALUATION FORM SENSICHECKER (XLS) ...

Request a quotation:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Interested in becoming international distribution partner? Please Contact:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

- Universally applicable for measuring both the shaft vibration and the axial shaft position.

- Save high investment costs for the application of discontinued vibration monitors while gaining increased monitoring quality and setting comfort!

- VibroUniT enables vibration monitoring, even during the critical startup period.

- The loop sensitivity is freely adjustable.

- Combinable with systems from any manufacturer; existing components (sensors, oscillators, extension cables) can be kept.

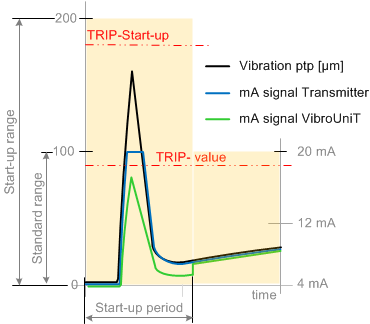

Monitoring of the critical startup period

Immediately after starting a machine, individual vibration measuring points are inherently designed to indicate an oscillation level above the shut-off values. Overriding the vibration monitor during the startup period is common practice, but is absolutely inadvisable. VibroUniT provides you with the ideal problem solution; the measuring range is automatically adapted to the operating conditions during startup.

The transmitter gives a - 20 mA signal that is proportional to the peak-to-peak vibration value; limit value monitoring is performed in a downstream system. Thanks to the automatic measuring range changeover, the same limit value always applies.

VibroUniT facilitates the correct setting of the loop sensitivity

We recommend that the loop sensitivity is determined at the start-up of the vibration measurement system; both the kmo probe holder and the kmo SensiChecker are suitable for this purpose. If the determined loop sensitivity is entered in VibroUniT, an optimum level of measuring and display accuracy can be achieved.

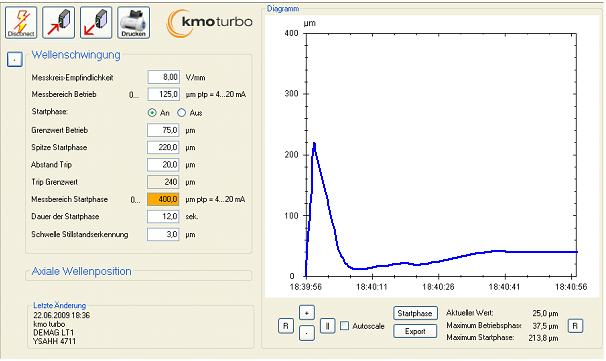

kmo VibroUniT is delivered with customer-specific parameter settings. All parameters can be changed via a parameterization interface in order to ensure that the system is optimally adapted to the respective operational requirements.

The signal course of the first 60 seconds after the startup is automatically recorded and evaluated in accordance with various criteria. The values can be read and graphically represented with the aid of the parameterization software.

VIBROUNIT PRODUCT BROCHURE (PDF) ...

Request a quotation:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Interested in becoming international distribution partner? Please Contact: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Systems for measuring shaft vibrations operate according to the eddy-current principle; non-contact measurement of the distance between the probe tip and the rotor surface. The probe has to be set to a distance or GAP of approx. 1.2 mm. A direct current signal proportional to the distance, the GAP voltage, can be measured at the outlet of the transmitter/oscillator/proximitor. Depending on the manufacturer, recommended values range from 8 to 10 VDC.

The setting process can be speeded up considerably with the aid of the GapTester. The GAP voltage is displayed via LEDs in the traffic light colors of red - yellow - green. Arrows below the LEDs indicate the required direction of rotation. When adjusting the distance, the LEDs initially change from red to yellow and then to green, until three green LEDs light up to indicate the optimum distance. The standard GapTester KS02-08/10 is factory set for the switchable GAP voltage values 8 VDC and 10 VDC. Other combinations (e.g. KS02-08/09 or KS02-09/10) are available on request.

The times in which the adjustment of the shaft vibration probes occupied two men over a longer period are over at last. These adjustments can now be performed by one person in just a fraction of the time: Thanks to the magnet on the back of the device, the GapTester can be attached to a convenient position of good visibility; the brightly illuminated LEDs can also be easily read from a distance.

Many of the transmitters/oscillators/proximitors on the market also provide the distance signal via a BNC connector. kmo turbo supplies the GapTester with a BNC-to-measuring-cable adapter or a measuring cable with a BNC connection. If there is no BNC connection, the GapTester has to be connected to the terminals GAP (+) and COM (-), using a standard measuring cable with flying leads or test prods.

PRODUCT BROCHURE GAPTESTER (PDF) ...

Request a quotation:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Interested in becoming international distribution partner? Please Contact: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

kmo turbo always favors the reverse mount variant (probes for sleeve mounting) as opposed to standard probes. The probe is always the same for both rotor vibration and shaft position measurement; the adaptation to the installation situation is performed via the probe holder.

kmo turbo has developed an own probe holder for the mounting of reverse mount eddy current sensors. This probe holder stands out positively in many respects compared with conventional fixing systems:

- Retrofitting can be performed on the kmo probe holder without extensive mechanical processing.

- Thanks to the adjustment range of 50 mm only a few different sleeve lengths are required, which simplifies potential stock keeping for spares.

- The distance of the probe to the shaft is set only once during the initial installation, and then nevermore. A reference surface ensures that the set distance is maintained, even after disassembly and reassembly.

- Thanks to an O-ring seal, oil leakage from the bearing housing through the probe holder is ruled out.

- A generously dimensioned terminal housing is provided to ensure a secure cable reception, including plug connection.

- The terminal housing made of non-conductive material provides reliable protection against ground fault or short circuit to ground.

- Dismantled probes are protected by robust protective sleeves.

We recommend the kmo GapTester for a reliable setting of the probe distance (GAP voltage); this device considerably speeds up the adjusting procedure.

Once set – nevermore readjusted!

The distance of the probe to the shaft surface (GAP) is set only once and permanently fixed. The originally set distance is maintained, even after disassembly and reassembly.

Terminal housing with multiple advantages

Generously dimensioned for secure cable reception without the risk of crushing and without an undershooting of the permissible bending radii. The terminal housing is positionable. The housing is made of non-conductive material to ensure against potential ground fault or short circuit to ground that can falsify measurement values. A circumferential groove at the inner bottom allows convenient storage of the cable overlength.

Protective cap for dismantled probe holder

Experience has shown that probes are often subject to damage after dismantling, e.g. as a result of incorrect storage. kmo turbo offers robust protective screw-on caps for the probe holders in order to ensure protection of the sensitive sensors. The protective cap can be stored in the connection head.

ORDER INFORMATION KS016 (PDF) ...

PRODUCT INFORMATION PROBE HOLDER KS016 (PDF) ...

Request a quotation:

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Interested in becoming international distribution partner? Please Contact: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!